Pet treats/Dog chews food Auto Meat Strips Dog Treats Processing Line

商品の詳細:

| 起源の場所: | チーナン、山東省 |

| ブランド名: | DARIN |

| 証明: | CE ISO9001 |

| モデル番号: | DR-126 |

お支払配送条件:

| 最小注文数量: | 1つはセット |

|---|---|

| 価格: | USD |

| パッケージの詳細: | 私達は適した長い旅行のための輸出標準的な木の場合をおよびローディング及び荷を下すこと供給できます。 |

| 受渡し時間: | 頭金を受け取った後45仕事日 |

| 支払条件: | T/T、L/C、ウェスタン・ユニオン、D/A |

| 供給の能力: | 1 年ごとの 50 セット |

|

詳細情報 |

|||

| 材料: | SUS304 | 使用法: | 肉は犬の御馳走を除去する |

|---|---|---|---|

| 保証: | 1年 | 容量: | 1時間あたりの300~500kg |

| 力: | 12kw | 次元: | 14*6*3m |

| 必要とされる労働者: | 2~3人の労働者 | 原物: | チーナンDarin |

| ハイライト: | dog food production line,pet food processing line |

||

製品の説明

Dog Food Jerky Treats Making Machine

Product Introduction:

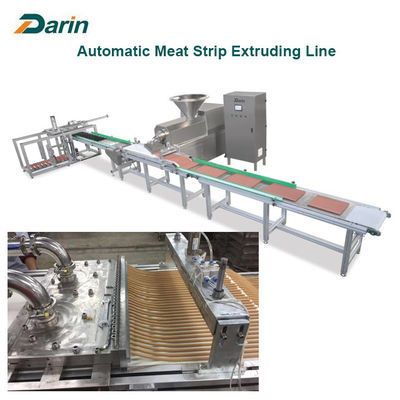

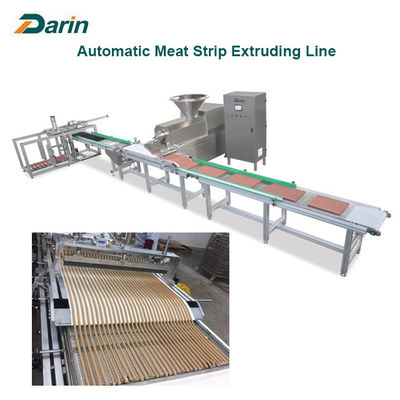

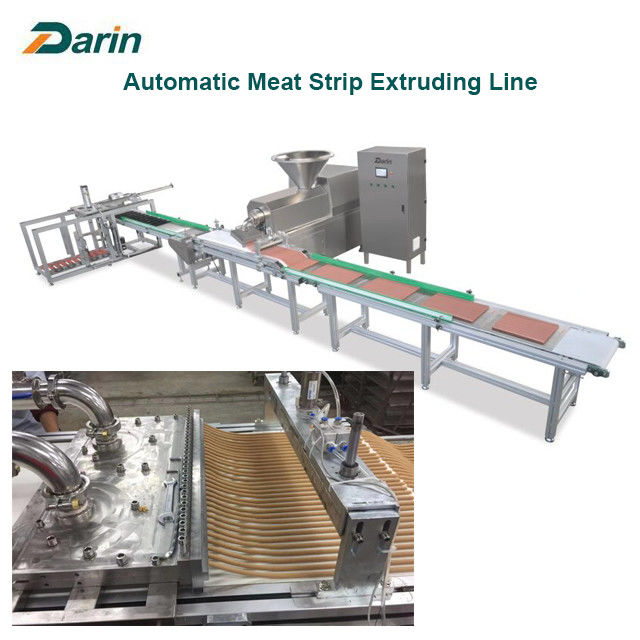

DR-126 meat strip extruding machine can extrude multi pieces of meat sticks. Different sizes and shapes can be made by changing the mold.

1. Especially used to produce high content (max 70-80%) meat products.

2. Patented design to produce meat strips with different shapes and sizes.

3. Stainless steel control cabinet, touch screen with a friendly interface, and fault display function.

4. The screw adopts a detachable structure and has a rust-proof treatment.

![]()

Conveyor Part

1. The conveyor is used to transport meat strips. In addition, the cutting device is mounted on this conveyor belt.

2. The conveying speed can be adjusted to meet various speeds.

3. Stainless steel meets food-grade materials, including mesh belts.

4. The upper layer is used to transport materials and cut materials. The lower layer is used to transport the tray.

![]()

Technical Parameters

| Output | Power | Required Worker | Voltage / Frequency | Dimension |

| 300-500kg/hr | 12kw | 2~3 | 380V / 50Hz | 15 x 6 x 3m |

![]()

Commissioning Service

1. We make accurate factory layout design according to customer’s factory size; if the customer needed, we could make workshop design with electricity power, water supply, gas power, material storage, final storages, worker’s restroom, etc.

2. After delivering machines to the client’s factory, we start to apply for the Visa to client’s country immediately; normally the vessel needs 20-60 days to the required port, so we have enough time to get the Visa. While the machines arrives your factory, our engineers are ready to start for the commissioning service.

3. 1-2 of our engineers will go to your factory to install and adjust the processing line to realize normal production at shortest time.

4. Our engineers have responsibility to train and teach the workers how to operate, clean, maintain and repair all the machines, until the workers could well operate the processing line.

5. It normally costs 10 days for the commissioning

service, and we supply 1 year guarantee from the date of completion of commissioning service.

6. The engineer’s round-trip flight tickets, accommodation and daily salary USD 60 are on client’s account.